PIPELINE Y STRAINERS

COD: IS16F

Pipeline Y strainers are filtration devices designed to remove debris and particulates from liquids in piping systems. Their Y-shaped design allows for easy installation and maintenance, facilitating cleaning without disrupting flow. Ideal for various industries, including water treatment and chemical processing, they help protect pumps and equipment from damage, ensuring system efficiency.

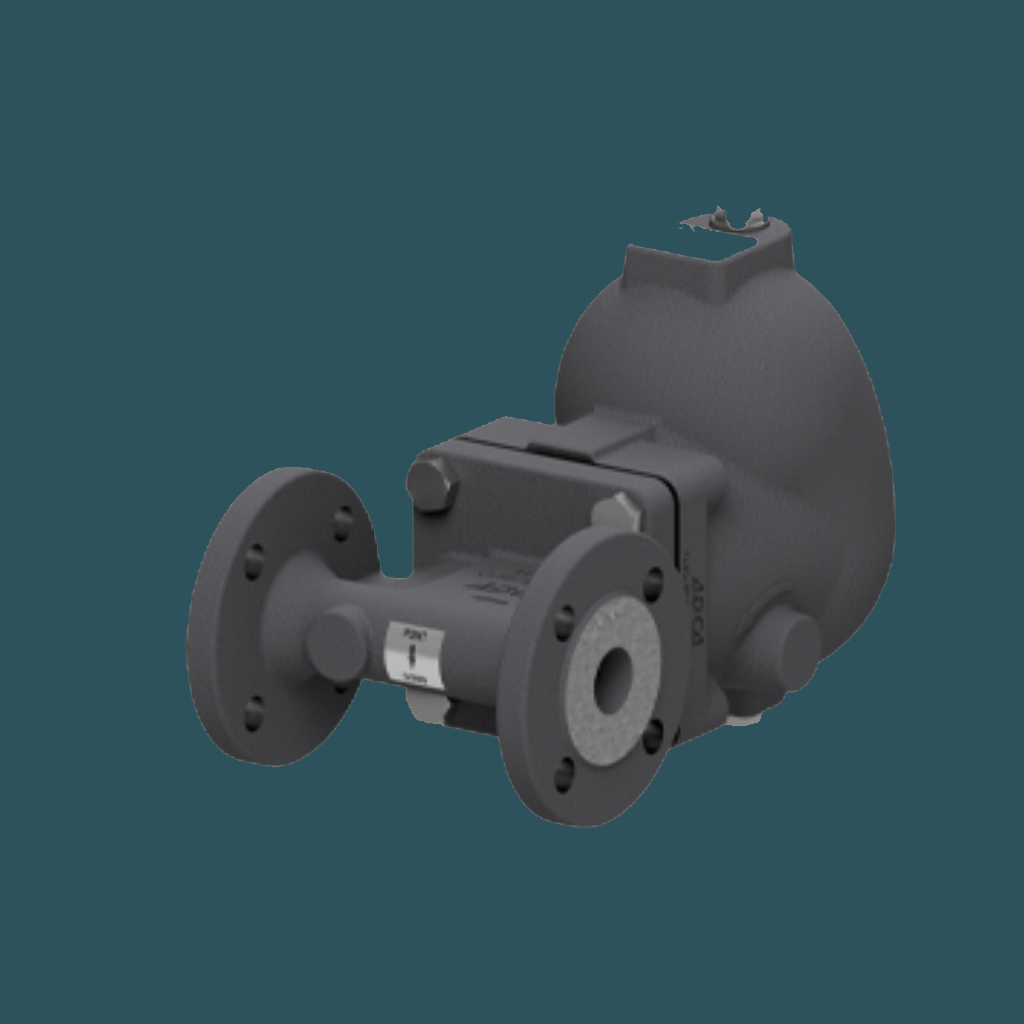

FL21 FLOAT AND THERMOSTATIC STEAM TRAPS

COD: FLT21

The FLT21 series of float and thermostatic steam traps features an integral air vent that facilitates the modulating discharge of condensate, ensuring optimal heat transfer within steam systems. This design is particularly suited for applications such as unit heaters, heat exchangers, dryers, and jacketed vessels, where continuous condensate removal is crucial for maintaining system efficiency and performance.

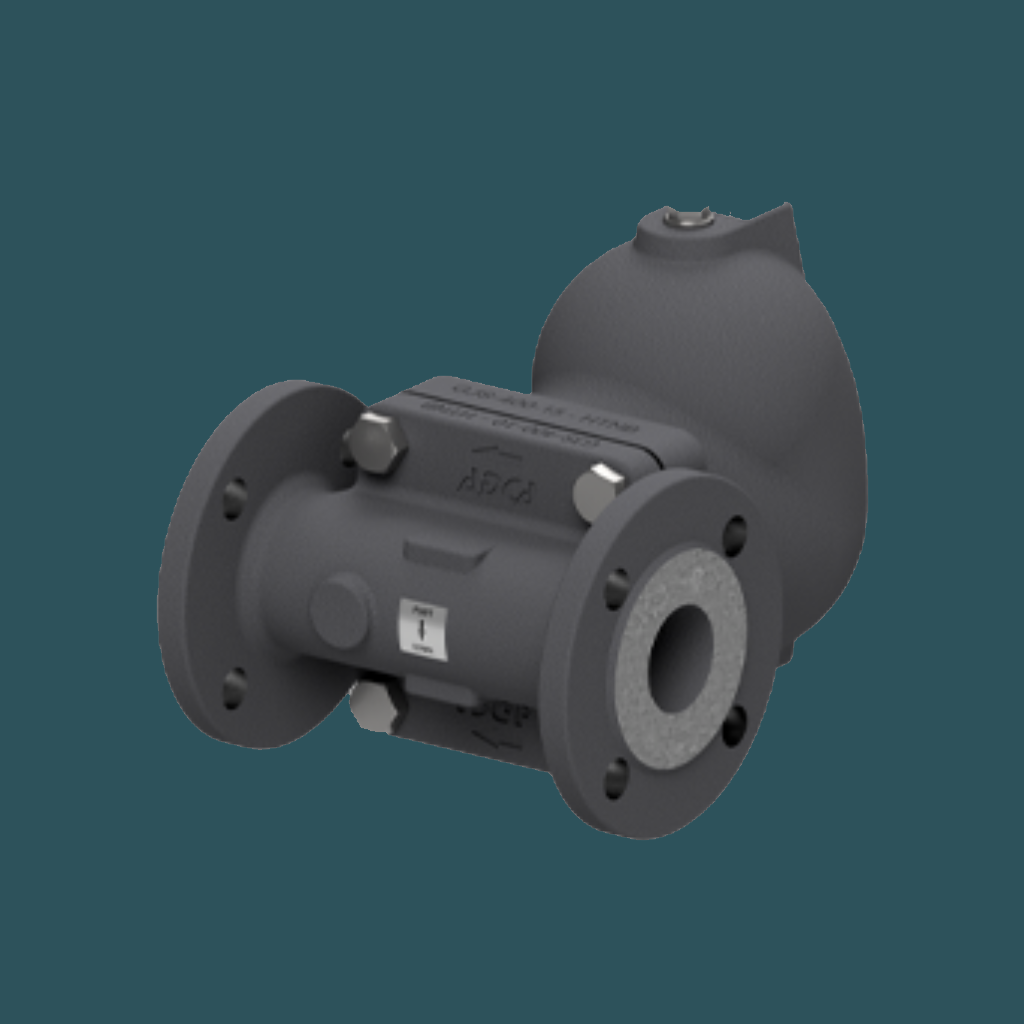

FLT25 FLOAT AND THERMOSTATIC STEAM TRAPS

COD: FLT25

The FLT25 series of float and thermostatic steam traps is equipped with an integral air vent, designed for the precise modulation of condensate discharge. This feature maximizes heat transfer efficiency in steam systems. The FLT25 is ideal for use in unit heaters, heat exchangers, dryers, jacketed vessels, and other applications where uninterrupted condensate removal is essential for optimal system performance.

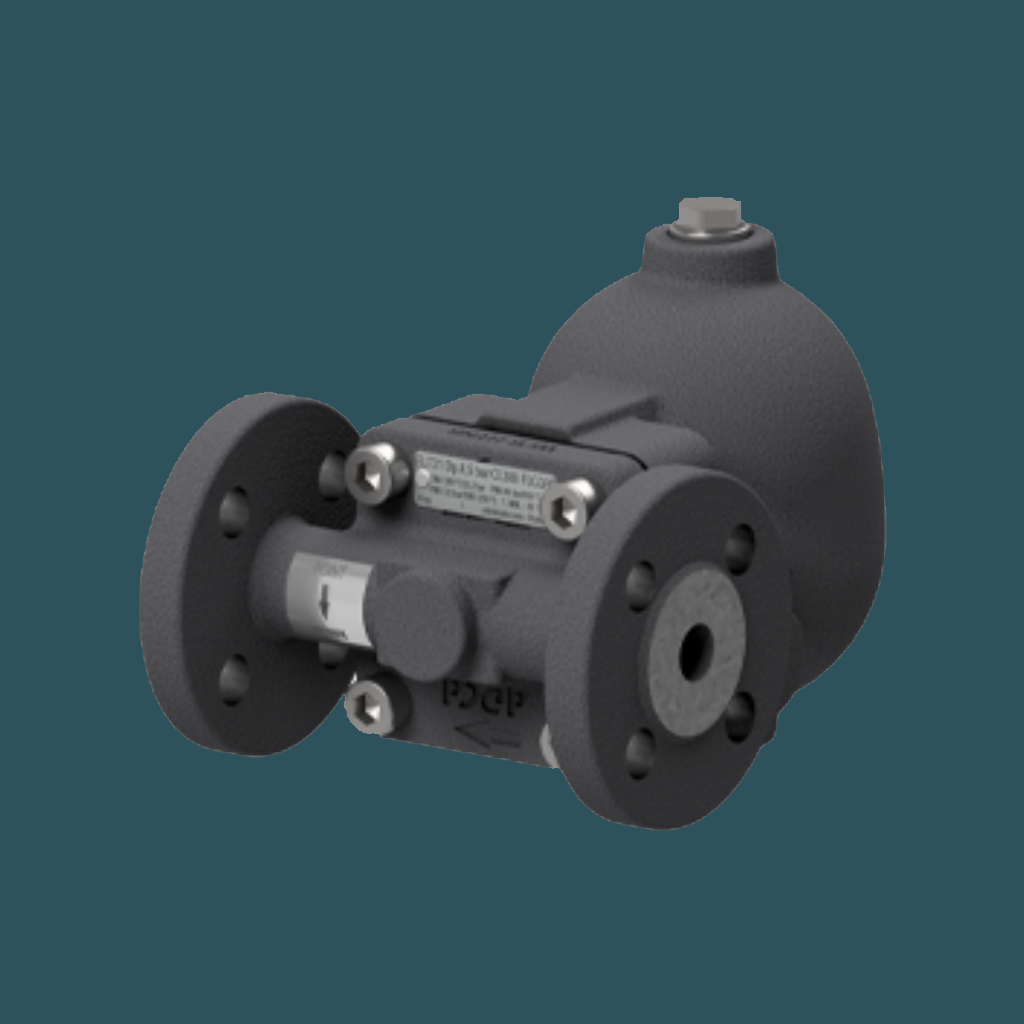

FLT27 FLOAT AND THERMOSTATIC STEAM TRAPS

COD: FLT27

The FLT27 series features float and thermostatic steam traps equipped with an integral air vent, designed to modulate condensate discharge effectively while maximizing heat transfer. This range is ideal for applications involving high flow capacities, such as unit heaters, heat exchangers, dryers, and jacketed vessels, where continuous condensate removal is crucial for maintaining system performance and efficiency.

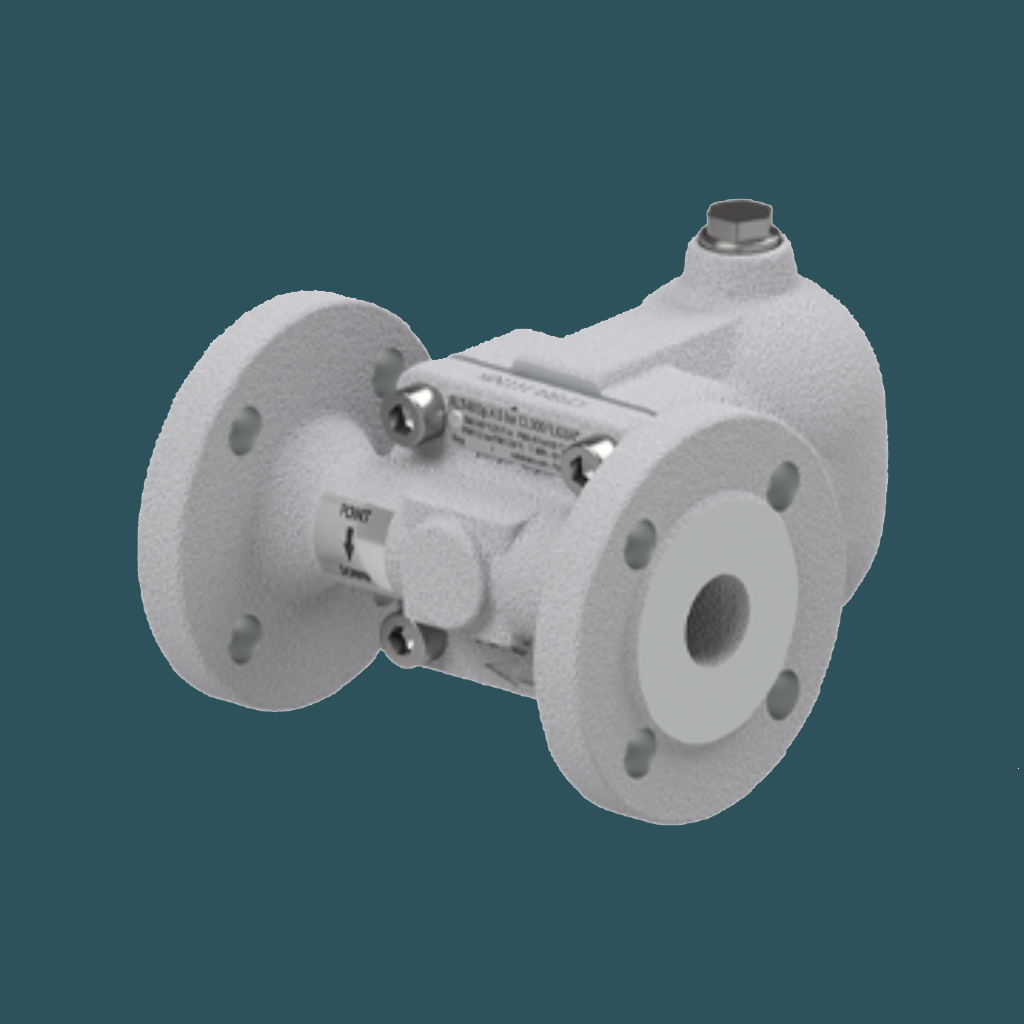

FLT29 FLOAT AND THERMOSTATIC STEAM TRAPS

COD: FLT29

The FLT29 series consists of float and thermostatic steam traps featuring an integral air vent, specifically designed for the efficient modulation of condensate discharge. This ensures optimal heat transfer within steam systems, making it well-suited for applications that require high flow capacities. Typical uses include unit heaters, heat exchangers, dryers, jacketed vessels, and other scenarios where continuous condensate removal is essential for maintaining performance and efficiency.

FLT29TW FLOAT AND THERMOSTATIC STEAM TRAPS

COD: FLT29TW

The FLT29TW series consists of high-capacity float and thermostatic steam traps featuring an integral air vent, designed for effective modulation of condensate discharge. This design ensures optimal heat transfer in steam systems, particularly in applications requiring high flow capacities. Commonly utilized in unit heaters, heat exchangers, dryers, jacketed vessels, and other settings where continuous condensate removal is critical, the FLT29TW enhances system efficiency and reliability.

FLT30 FLOAT AND THERMOSTATIC STEAM TRAPS

COD: FLT30

The FLT30 series features float and thermostatic steam traps equipped with an integral air vent, designed to effectively modulate the discharge of condensate while ensuring maximum heat transfer in steam systems. This series is ideal for applications such as unit heaters, heat exchangers, dryers, and jacketed vessels, where continuous condensate removal is critical for optimal system performance and efficiency.

FLT37 FLOAT AND THERMOSTATIC STEAM TRAPS

COD: FLT37

The FLT37 series consists of float and thermostatic steam traps made from carbon steel, suitable for both low and high-pressure applications. Featuring an integral air vent, these traps are designed for effective modulation of condensate discharge, ensuring maximum heat transfer in steam systems. Ideal for unit heaters, heat exchangers, dryers, jacketed vessels, and all applications requiring continuous discharge and high flow capacities, the FLT37 series is essential for maintaining optimal system performance and efficiency.

FLT31 FLOAT AND THERMOSTATIC STEAM TRAPS

COD: FLT31

The FLT31 series comprises float and thermostatic steam traps made from carbon steel, suitable for low and high-pressure applications. Featuring an integral air vent, these traps are designed to modulate the discharge of condensate effectively, ensuring maximum heat transfer within steam systems. Typical applications include unit heaters, heat exchangers, dryers, and jacketed vessels, where continuous condensate removal is essential for maintaining optimal system performance and efficiency.

FLT35 FLOAT AND THERMOSTATIC STEAM TRAPS

COD: FLT35

The FLT35 series features float and thermostatic steam traps constructed from carbon steel, designed for both low and high-pressure applications. Equipped with an integral air vent, these traps effectively modulate condensate discharge, ensuring maximum heat transfer in steam systems. Typical applications include unit heaters, heat exchangers, dryers, and jacketed vessels, where continuous discharge is critical for optimal system performance and efficiency.

FLT39 FLOAT AND THERMOSTATIC STEAM TRAPS

COD: FLT39

The FLT39 series features float and thermostatic steam traps constructed from carbon steel, designed for low and high-pressure applications. With an integral air vent, these traps effectively modulate the discharge of condensate, ensuring optimal heat transfer within steam systems. They are well-suited for unit heaters, heat exchangers, dryers, jacketed vessels, and other applications where continuous discharge and high flow capacities are critical for maintaining system performance and efficiency.

FLT39TW FLOAT AND THERMOSTATIC STEAM TRAPS

COD: FLT39TW

The FLT39TW series consists of high-capacity float and thermostatic steam traps made from carbon steel, suitable for both low and high-pressure applications. Featuring an integral air vent, these traps are designed for effective modulation of condensate discharge, ensuring maximum heat transfer in steam systems. Ideal for unit heaters, heat exchangers, dryers, jacketed vessels, and other applications requiring continuous discharge and high flow capacities, the FLT39TW series is essential for optimizing system performance and efficiency.

FLT40 FLOAT AND THERMOSTATIC STEAM TRAPS

COD: FLT40

The FLT40 series features float and thermostatic steam traps constructed from stainless steel, designed for both low and high-pressure applications. With an integral air vent, these traps effectively modulate condensate discharge, ensuring maximum heat transfer in steam systems. Typical applications include unit heaters, heat exchangers, dryers, jacketed vessels, and other settings where continuous discharge is essential for maintaining optimal system performance and efficiency.

FLT41 FLOAT AND THERMOSTATIC STEAM TRAPS

COD: FLT41

The FLT41 series comprises float and thermostatic steam traps made from stainless steel, suitable for low and high-pressure applications. Featuring an integral air vent, these traps are designed to modulate condensate discharge effectively, ensuring maximum heat transfer in steam systems. Typical applications include unit heaters, heat exchangers, dryers, jacketed vessels, and other situations where continuous discharge is critical for optimal system performance and efficiency.

FLT45 FLOAT AND THERMOSTATIC STEAM TRAPS

COD: FLT45

The FLT45 series features float and thermostatic steam traps constructed from stainless steel, designed for both low and high-pressure applications. With an integral air vent, these traps effectively modulate condensate discharge, ensuring optimal heat transfer in steam systems. They are ideal for applications such as unit heaters, heat exchangers, dryers, jacketed vessels, and other scenarios where continuous discharge is essential for maintaining system performance and efficiency.

FLT47 FLOAT AND THERMOSTATIC STEAM TRAPS

COD: FLT47

The FLT47 series consists of float and thermostatic steam traps made from stainless steel, suitable for both low and high-pressure applications. Featuring an integral air vent, these traps are designed to modulate condensate discharge effectively, ensuring maximum heat transfer in steam systems. They are particularly suited for unit heaters, heat exchangers, dryers, jacketed vessels, and other applications where continuous discharge and high flow capacities are critical for optimal system performance and efficiency.

FLT49 FLOAT AND THERMOSTATIC STEAM TRAPS

COD: FLT49

The FLT49 series features float and thermostatic steam traps constructed from stainless steel, designed for both low and high-pressure applications. With an integral air vent, these traps effectively modulate condensate discharge, ensuring optimal heat transfer in steam systems. They are ideal for unit heaters, heat exchangers, dryers, jacketed vessels, and other applications where continuous discharge and high flow capacities are essential for maintaining system performance and efficiency.

FLT49TW FLOAT AND THERMOSTATIC STEAM TRAPS

COD: FLT49TW

The FLT49TW series consists of high-capacity float and thermostatic steam traps made from stainless steel, suitable for both low and high-pressure applications. Featuring an integral air vent, these traps are designed for effective modulation of condensate discharge, ensuring maximum heat transfer in steam systems. They are ideal for unit heaters, heat exchangers, dryers, jacketed vessels, and other applications where continuous discharge and high flow capacities are essential for optimal system performance and efficiency.

FLT22 FLOAT AND THERMOSTATIC STEAM TRAPS

COD: FLT22

The FLT22 series features high-capacity float and thermostatic steam traps made from fabricated steel. Designed with an integral air vent, they efficiently modulate condensate discharge to ensure maximum heat transfer. Ideal for applications requiring continuous drainage and high loads, these traps are essential for optimal system performance.

FLT312 / FLT314 FLOAT AND THERMOSTATIC STEAM TRAPS

COD: FLT312 / FLT314

The FLT312 and FLT314 series consist of high-capacity float and thermostatic steam traps made from fabricated steel. Featuring an integral air vent, these traps are designed to modulate condensate discharge for maximum heat transfer. They are ideal for applications requiring continuous drainage and high loads, ensuring optimal system efficiency and performance.

FLT314TW FLOAT AND THERMOSTATIC STEAM TRAPS

COD: FLT314TW

The FLT314TW series features high-capacity float and thermostatic steam traps constructed from fabricated steel. With an integral air vent, these traps efficiently modulate condensate discharge to maximize heat transfer. They are specifically designed for applications where continuous drainage and high loads are essential, ensuring optimal system performance.

FLT50-FLT65S FLOAT AND THERMOSTATIC STEAM TRAPS

COD: FLT50 / FLT65S

The FLT50 and FLT65 series consist of high-capacity float and thermostatic steam traps made from fabricated steel. Featuring an integral air vent, these traps are designed to modulate condensate discharge for maximum heat transfer. They are ideal for applications requiring continuous drainage and high loads, ensuring optimal system efficiency and performance.

FLT80 FLOAT AND THERMOSTATIC STEAM TRAPS

COD: FLT80

The FLT80 series features high-capacity float and thermostatic steam traps constructed from fabricated steel. With an integral air vent, these traps effectively modulate condensate discharge to maximize heat transfer. They are specifically designed for applications requiring continuous drainage and high loads, ensuring optimal system performance and efficiency.

FLT151 FLOAT AND THERMOSTATIC STEAM TRAPS

COD: FLT151

The FLT151 series consists of high-capacity float and thermostatic steam traps made from fabricated steel. Featuring an integral air vent, these traps are designed to modulate condensate discharge for maximum heat transfer. They are specifically suited for applications with continuous drainage and extremely high loads, making them ideal for use in sugar and alcohol refineries.

TH13A THERMOSTATIC STEAM TRAPS AND AIR ELIMINATORS

COD: TH13A

The TH13A series thermostatic steam traps and air eliminators are compact devices crafted from stainless steel, designed to efficiently manage steam in various process equipment, including kettle cookers, sterilizers, and laundry machinery. Their small footprint allows for easy integration into diverse systems, effectively removing air and non-condensable gases while maintaining optimal steam flow. This enhances the efficiency of operations in food processing, chemical applications, and laundry services, ensuring reliable performance and prolonged equipment life.

TH32 THERMOSTATIC STEAM TRAPS AND AIR VENTS

COD: TH32

The TH32 line of thermostatic steam traps and air vents, constructed from durable stainless steel, is engineered for effective steam management in process equipment like kettle cookers, sterilizers, and laundry systems. These traps efficiently eliminate air and non-condensable gases, ensuring consistent steam performance and preventing pressure buildup. Their reliable operation is crucial for industries such as food processing and chemicals, contributing to enhanced efficiency and equipment longevity.

TH21 THERMOSTATIC STEAM TRAPS AND AIR ELIMINATORS

COD: TH21

The TH21 series thermostatic steam traps and air eliminators, crafted from stainless steel, are ideal for kettle cookers, sterilizers, and laundry equipment. They effectively remove air and non-condensable gases, ensuring efficient steam flow and optimal performance in food processing and chemical industries.

TH35-2-3 THERMOSTATIC STEAM TRAPS AND AIR ELIMINATORS

COD: TH35

The TH35 series thermostatic steam traps and air eliminators, made from stainless steel, are tailored for kettle cookers, sterilizers, and laundry systems. They effectively manage air and non-condensable gases, promoting efficient steam operation and enhancing reliability in food processing and chemical applications.

TH36 THERMOSTATIC STEAM TRAPS AND AIR VENTS

COD: TH36

The TH36 series thermostatic steam traps and air vents, constructed from stainless steel, are engineered for high discharge capacities in kettle cookers, sterilizers, and laundry equipment. They efficiently eliminate air and non-condensable gases, ensuring optimal steam flow and performance in demanding food processing and chemical applications.

TSW22 THERMOSTATIC STEAM TRAPS AND AIR ELIMINATORS

COD: TSW22

The TSW22 all stainless steel thermostatic steam traps and air eliminators are designed for kettle cookers, sterilizers, and laundry equipment. Their compact size makes them versatile for various applications, efficiently removing air and non-condensable gases to ensure optimal steam performance in food processing and chemical industries.

UFS32 FLOAT AND THERMOSTATIC STEAM TRAPS

COD: UFS32

The UFS32 series float and thermostatic steam traps, crafted from stainless steel, are maintenance-free and sealed for dependable performance. Specifically designed for low and medium pressure steam, they are ideal for a variety of heating and process equipment. Typical applications include unit heaters, heat exchangers, driers, and jacketed vessels, where continuous drainage is essential for optimal operation.

UTS22 THERMOSTATIC STEAM TRAPS AND AIR ELIMINATORS

COD: UTS22

The UTS22 series thermostatic steam traps and air eliminators, constructed entirely of stainless steel, are maintenance-free and sealed for reliable operation. Designed for use in process equipment such as kettle cookers, sterilizers, and laundry machinery, these traps ensure efficient steam management. They are compatible with UCX universal connectors and CTS4U compact stations, allowing for versatile installation options in various applications.

TSS7 BALANCED PRESSURE THERMOSTATIC STEAM TRAPS

COD: TSS7

The ADCAPure TSS7 all-stainless steel thermostatic steam traps and air vents are purpose-built for hygienic applications like reactors, CIP/SIP systems, autoclaves, sterilizers, and distribution lines in clean and pure steam systems. Their compact design makes them suitable for use with a diverse range of equipment.

TSS6 BALANCED PRESSURE THERMOSTATIC STEAM TRAPS

COD: TSS6

The ADCAPure TSS6 all-stainless steel thermostatic steam traps and air vents are engineered for hygienic applications, such as reactors, CIP/SIP, autoclaves, sterilizers, and distribution lines in clean and pure steam systems. Their compact size makes them well-suited for use with a variety of equipment.

TSS6H BALANCED PRESSURE THERMOSTATIC STEAM TRAPS

COD: TSS6H

The TSS6H thermostatic steam traps and air vents are specifically designed for hygienic applications, including reactors, CIP/SIP systems, autoclaves, sterilizers, and steam distribution lines. Their compact size makes them ideal for a wide range of equipment. The sensitive thermostatic element reacts to minimal sub-cooling, opening at approximately 2°C below the saturated steam temperature.

TSS6A BALANCED PRESSURE THERMOSTATIC STEAM TRAPS

COD: TSS6A

The TSS6A thermostatic steam traps and air vents are crafted for use in hygienic environments such as reactors, CIP/SIP processes, autoclaves, sterilizers, and steam distribution pipelines. Their compact size allows them to easily integrate with various types of equipment. Designed for pure and clean steam systems, they ensure reliable and efficient operation across multiple applications.

SSI115 DIRECT STEAM INJECTOR

COD: SSI115

The ADCAPure SSI115 is a direct steam injector entirely constructed from 316L stainless steel. It is designed for the rapid heating of both still and flowing media within tanks and mixers, making it particularly well-suited for applications in the food and beverage industry.